Free Case Study

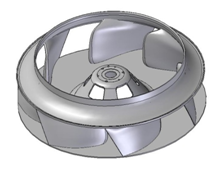

Daikin Industries Improves HVAC Fan Efficiencies Using TURBOdesign1

ADT's Case Study with Daikin Industries.

What's inside?

Daikin is actively involved in confronting global environmental problems as part of its corporate responsibility as a leading global manufacturer of air conditioning equipment. For these reasons, when it came time to develop an innovative fan design for a new line of air conditioning units, Daikin engineers set out to use the latest, most capable technology to develop even more efficient systems. They used the 3D inverse design technology of the TURBOdesign Suite by Advanced Design Technology.

“We wanted to improve air conditioning fan efficiency and did it by using TURBOdesign1,” said Toru Iwata, Researcher, Daikin Industries, Environmental Technology Laboratory. “We decided that 3D inverse design technology was needed to achieve the efficiency we wanted while shortening our design time. Therefore, we chose TURBOdesign1 software.”

In this case study, you will:

- Why being a leader in confronting global environmental problems led Daikin to want to improve their fan designs for efficiency.

- How 3D Inverse Design was able to develop new designs beyond the limitations of their previous approach.

- See how much RoI Daikin achieved by using TURBOdesign Suite, including performance gains and time saved.