Advanced Design Technology presented our paper on 'Optimisation of a pump-as-turbine runner using a 3D inverse design methodology' at the next Symposium on Hydraulic Machinery and Systems in Kyoto, the ancient capital of Japan, in September 2018.

IAHR 2018 in Kyoto offered an opportunity to gather scientists and engineers from all over the world to discuss the most recent advances in theoretical, experimental and computational research as well as the latest challenges faced by the industry.

Hydraulic machinery and systems are the key components for the sustainable development of energy and water resources including various transport process of liquids. For more effective and efficient utilisation of hydraulic machinery and systems, it is important to exchange up-to-date information on R&D, Numerical Analysis, Design, Operation and Monitoring of hydraulic machinery and systems.

Complete the short form below.

Abstract: One of the society's biggest current challenges is the mitigation release of greenhouse gas emission into the atmosphere while setting the basis for a sustainable development. As a result, climate-related factors are currently driving the adaptation of the power generation and energy storage sectors.

Pumped-storage hydroelectricity is today the world’s largest contributor to grid energy storage and its success is based on the design and ability of an impeller to perform as either a pump or a turbine by reversing the rotation direction.

In this paper, we discuss the performance of a pump-as-turbine runner for pumped storage hydroelectricity applications. This is analysed with a specific focus on the trade-off between the pump and the turbine working modes.

The principles of the pump and turbine turbomachinery components are well known. However, the design of components for challenging turbomachinery-based schemes like the ones explained requires a flexible method that enables the exploration of trade-offs.

We will present the optimisation of a pump-as-turbine runner using a 3D inverse design method. The baseline design is based on an existing runner designed with TURBOdesign1 (TD1) this is then optimised by the genetic algorithm in Isight.

In the work presented, the performance is optimised using TURBOdesign Optima (TDOptima) and keeping the same meridional profile, stacking characteristics and work distribution in the pump mode. The baseline runner design will be further optimised by minimising the secondary flow and profile loss factors.

Left: Velocity contours at midspan at design volumetric flow rate. Turbine mode. Right: Circumferentially area averaged streamwise velocity in the meridional plane. Turbine mode.

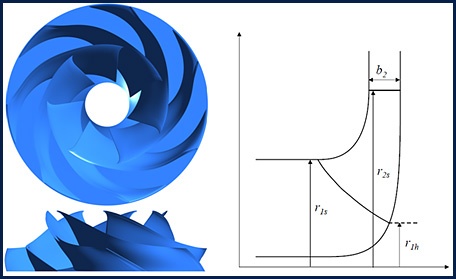

Left: Runner B geometry. Right: Meridional profile. r1h = 63:5 mm, r1s = 135 mm, r2 = 224 mm, and b2 = 51 mm.

What to expect?

In this paper, we will provide you with an understanding on how you can achieve a better and more efficient design of a pump-as-turbine case with multiple-objectives and multi-points conditions using the inverse design code of TURBOdesign1 and TURBOdesign Optima to optimise the performance.

In the presentation, you will see the detailed process of using our code and method to redesign and optimise a PAT in a shorter time.

View the full program (paper 357).

We'll be at the IAHR 2018 to present our paper to the world of pumps and hydraulic turbines. We invite you to join us for coffee after the presentation for an exclusive one to one consultation to discuss your design objectives and challenges in the pumps and hydraulic turbine design process.

The consultation session will include:

We provide software and services for the design and optimization of turbomachinery, based on our unique 3D Inverse Design technology. Our tools and services help customers achieve innovative “breakthrough” designs, delivering market leading solutions at dramatically reduced development costs.

ADT, headquartered in London, UK, was established in 1999 as a joint venture between University College London and The Ebara Research Co Limited of Japan. We are considered as one of the leading global turbomachinery design software providers, with our TURBOdesign Suite tool set in use across a very wide range of applications and sectors.

Our design consultancy services deliver cutting-edge solutions to our global customers. Whether the task involves a complete solution, from concept to final design for manufacturing, or is facing challenging multi-point / multi-objective design optimization, we work closely with our customers and support them throughout the entire design process.

Learn more about Advanced Design Technology.

For more information or further inquiries please contact:

Contact person: Dr. Peng Wang. 王鹏博士

Tel: +86 (0) 21 8022 0940 or +86 (0) 21 8022 0942

Mobile: +86 18816519378

Email: p.wang@adtechnology.cn

Web: www.adtechnology.cn